Polypropylene (PP) is a semi-crystalline thermoplastic polymer, synthesized from the polymerization of propylene, which belongs to the group of polyolefins. This material is characterized by its high resistance to various chemical solvents, as well as to alkalis and acids. It has remarkable rigidity, hardness and strength, although it has minimal resilience. At normal temperatures, polypropylene is resistant to cracks, but it can become brittle at temperatures below 0ºC. The continuous use temperature ranges from +5ºC to +100ºC, making it suitable for a wide variety of industrial applications.

Commercially introduced in 1957, polypropylene is currently the second most widely used plastic in the world. Its versatility allows it to be used in textiles, packaging, medical devices, laboratory equipment, automotive components, etc. Polypropylene polymerization is carried out through catalytic processes, producing a material with balanced properties and excellent chemical resistance. In addition, polypropylene is light, weldable and has low water absorption rates.

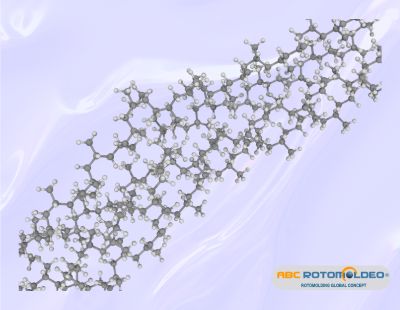

Polypropylene’s chemical structure, similar to polyethylene but with key differences, gives it unique characteristics that broaden its applications. It is a linear polymer derived from propylene, a gas present in crude oil and refining gases. Its properties include high purity, good electrical insulation properties and the ability to be molded into complex shapes with different thicknesses.

attributes

This material, derived from the polymerization of propylene, stands out for its resistance to various chemical solvents, alkalis and acids. In addition, polypropylene has a structure that gives it rigidity, hardness and high impact resistance. Although it is not particularly resilient, its low cost and ease of processing make it ideal for a wide range of applications, from food packaging to automotive components and medical devices.

One of the main physical properties of polypropylene is its low density, which varies between 0.89 and 0.91 g/cm³, making it one of the lightest commercial polymers. This characteristic, together with its high thermal resistance, with a melting point around 165°C, makes it suitable for applications that require stability at high temperatures. In addition, polypropylene has very low moisture absorption, allowing it to maintain its structural integrity in humid environments and in contact with water.

In terms of its mechanical properties, polypropylene offers excellent tensile strength, with a yield strength of approximately 35 MPa and an elongation at break of 650%. These properties make it ideal for applications requiring durable materials that are resistant to deformation under load. PP is also known for its good impact resistance, making it suitable for the manufacture of components subject to repeated mechanical stress, such as bumpers and battery boxes in the automotive industry.

Polypropylene is also valued for its electrical properties, making it an excellent insulator. It has a dielectric strength greater than 10^13 ohms and a dielectric coefficient of 2.25, making it suitable for applications in electrical and electronic components. Additionally, its low thermal conductivity of 0.22 W/(K-m) contributes to its insulating ability, which is beneficial in applications requiring thermal and electrical insulation.

In terms of sustainability, polypropylene is recyclable and is identified by recycling code number 5. Its ability to be recycled and reused in new products makes it an attractive option to reduce the environmental impact of plastic materials. In addition, its resistance to degradation by chemical agents and its durability contribute to the longevity of products made from this material, thus reducing the need for frequent replacements and the resulting waste.

Ultimately, polypropylene is a versatile, high-performance material that offers a unique combination of physical, mechanical and chemical properties. Its ability to be used in a wide variety of industrial and commercial applications, coupled with its sustainability and recyclability, make it an essential polymer in modern manufacturing.

There are two categories of polypropylene: homopolymers and copolymers.

Polypropylene is classified into two main categories: homopolymers and copolymers. Homopolymers are composed of repeating units of a single monomer, while copolymers combine two or more different monomers in their structure.

This adaptability of polypropylene, through the introduction of special additives or by modifying its manufacturing process, has earned it the nickname “steel” in the plastics industry due to its versatility and multiple applications. Each type of polypropylene is better suited to certain specific uses, offering different properties and benefits.

Homopolymers: What are they and what are their properties?

A homopolymer is a polymer composed of only one type of monomer throughout its entire chain. Homopolymer polypropylene, one of the most common forms, is characterized by its high strength-to-weight ratio, excellent performance in corrosive environments, and nontoxicity. This material also has high stiffness and high tensile strength, making it ideal for applications requiring durability and stability. Additionally, its good weldability and chemical resistance make it suitable for food handling and other industrial uses.

Copolymers: What are they and what are their properties?

A copolymer is made up of two or more different monomers linked together to create a polymer chain. Copolymers can be block, random, or alternating. Block copolymers have monomers arranged in specific sequences, improving impact resistance.

Random copolymers mix monomers in no specific order, resulting in more malleable and clear materials. Alternating copolymers have monomers arranged in alternating fashion, combining unique properties of each monomer. These polymers offer excellent heat resistance, can be thermoplastic or thermosetting, and are used in a wide range of industrial products.

Differences between homopolymers and copolymers

Homopolymers and copolymers differ mainly in their structure and resulting properties. Homopolymers are made up of only one type of monomer, which gives them high crystallinity and mechanical strength.

On the other hand, copolymers, by combining different monomers, present greater flexibility and impact resistance. Block copolymers are particularly useful in applications requiring high impact resistance, while random copolymers are preferred for products requiring clarity and malleability.

ABC ROTOMOLDEO and its knowledge about polypropylene

At ABC ROTOMOLDEO we are experts in the manufacturing of plastic parts using rotational moulding. We work with polypropylene in our processes and take advantage of the unique advantages of this material, such as its chemical resistance, flexibility and durability.

Additionally, rotational molding enables us to adapt to any sector due to the versatility of the plastic materials used, from the food and healthcare sectors to the energy sector. Contact us for more information on how we can bring your ideas to life by choosing the most suitable raw materials.

If you want to carry out a custom project with us, do not hesitate to contact us.

If you found this article interesting, we suggest the following readings:

· Polyethylene: What is it? Uses in rotomolding

· Rotomoulding deposits: diverse applications for any industry